"Productivity gains allow us to have bigger margins and win more work. The STRATUS Manufacturing and Installation Labels (Mail) have allowed us to gain double digit productivity savings. The goal is no more paper and to install directly from the label. That’s how we build at Postler." - Jesse Gorman

Postler & Jaeckle started working with STRATUS in 2015 and had a goal of eliminating paper in the shop, having better efficiency in cutting and using a barcode label. STRATUS quickly took off and while initially it was focused on shop workflows it has now gained traction in quality control, logistics, project management and the field. The labels have been a major component of their continuous ROI with STRATUS, the latest of which is hangers.

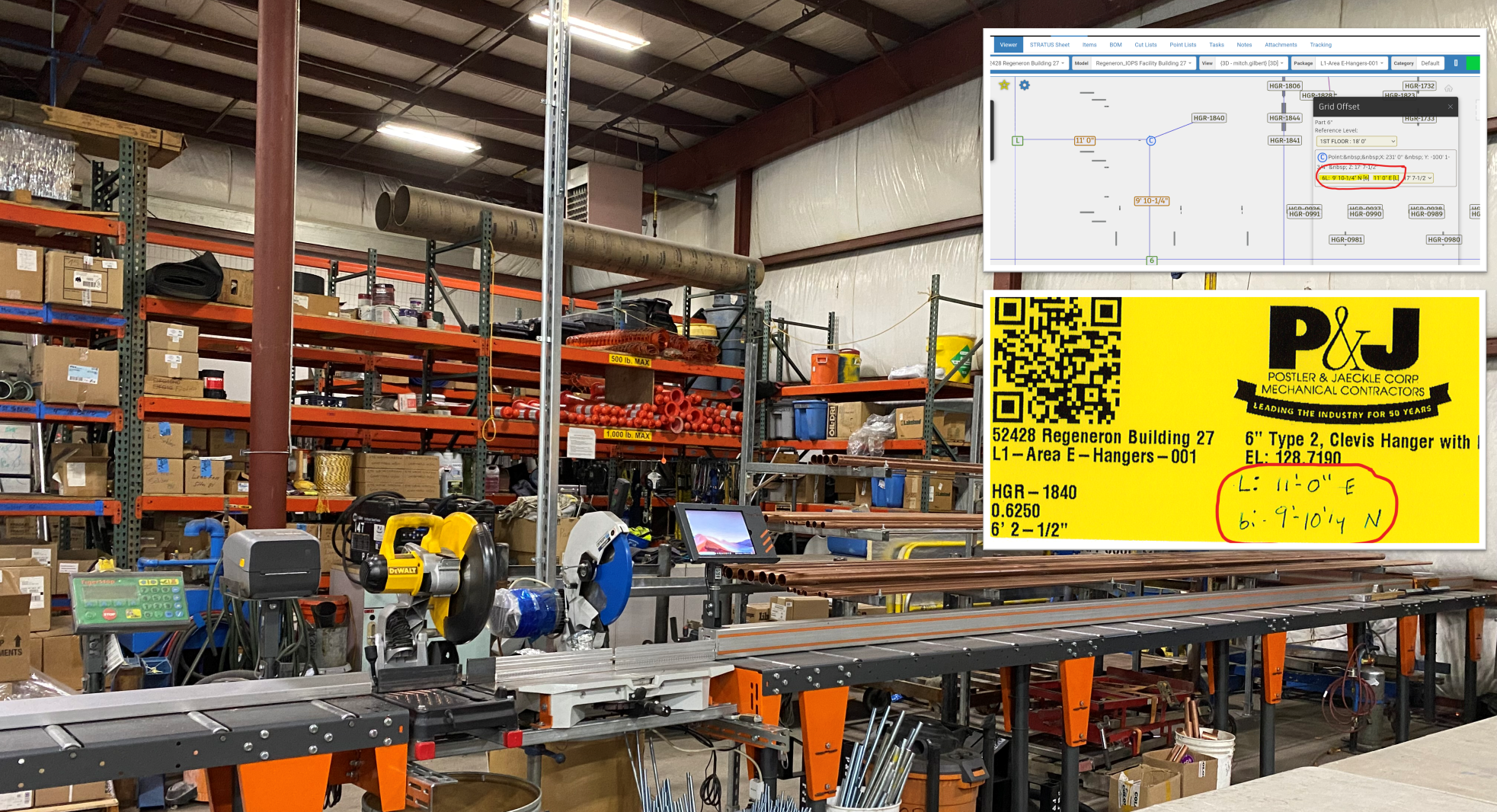

To reduce the amount of time field workers spent laying out hanger points or searching for material Postler Jaeckle uses STRATUS to do the following: create hanger packages, pre-cut hangers in the fabrication shop and generate a labels. STRATUS extracts information directly from the model, makes it available in a digital model viewer and prints it directly on the label.

They previously tried different methods for hanger installation. Such as: sending a person ahead with a tablet to layout points on the floor, having an installer use the iPad to continuously find the location of one hanger, use the total station or create a shop drawing with dimensions and tags. While those options helped, they would create a bottleneck further in the process. Often the field was left depending on one person with an iPad or total station or waiting for drafting to complete a sometimes difficult to read install drawing.

STRATUS bypassed all those issues by simply creating a label designed for manufacturing and installation. Labels can include information like hanger number, rod size, rod length, hanger type, elevation, attachment type and grid offset. The grid offset tool in STRATUS tells a user exactly how far east/west or north/south of a gridline to install a hanger. Now, an installer can easily read the hanger coordinates on the label and install a hanger without using a tablet or referencing install drawings.

In a recent project of over 10,000 hangers Postler & Jaeckle prefabbed most of them in packages of roughly 250 hangers with a built-in allowance for rod length adjustment. Although they had 3,000 hangers built in the truck before being able to install the first one, they didn’t have any issues with slab sag or structure. Overall, less than 1.5% of the 10,000 hangers were duplicated or changed. That project solidified manufacturing from labels reduces material handling and dependences on tablets or internet. Enabling Postler and Jaeckle to install with smaller crews and reduced supervision time.

Utilizing labels for efficiency does not stop with hangers. Postler & Jaeckle continues to pioneer innovation with labels for pipe installation. Using a system of sequential lettering labels, the field crew can install assemblies similar to an erector set. Starting with a STRATUS “reference” label to locate one specific part in a package coupled with the grid offset functionality, the “A-A” or “B-B” labels on each end of every assembly quickly show the orientation of assemblies. While seemingly simple, the orange stickers provide an install roadmap for the field.

Postler & Jaeckle’s commitment to embracing streamlined and impactful solutions, drastically decreased redundancies, increased efficiency and contributed to the quality of their finished product. In a state where journeyman labor is $1.20 a minute saving minutes brings value quickly. As demonstrated by Postler & Jaeckle success building directly from labels produced from STRATUS, picking up efficiencies with labels is a quickly attainable win for any company.

Postler & Jaeckle’s Label Example

Postler & Jaeckle’s Label Example

Grid offset values in STRATUS

Grid offset values in STRATUS

Prefabricated hangers staged in the shop

Prefabricated hangers staged in the shop

Prefabricated hangers on carts at the jobsite

Prefabricated hangers on carts at the jobsite

STRATUS reference label + sequential letter label

.png?width=70&name=Untitled%20design%20(12).png)